Part 1 – An Introduction to Device Maintenance Events

This is the first of a 2-part article about the maintenance event feature of E-Quip. This article introduces the concept of events and shows a simple automated event mechanism. The 2nd article will go into this subject in much greater depth.

A maintenance event is any activity that must take place at some fixed interval on a device. Examples might be “Battery Change”, “Replace Filter” etc.

Suppose that the battery for a device must be changed every year, and the device is on 6-monthly, annual and 5-yearly PPM Schedules. If you understand how PPM Schedules work then you will know that there will always be 3 non-completed jobs for this device, one for each schedule. (If you didn’t know that, check out some of the articles on this blog on PPM management).

It is easy to envisage situations where the annual battery change might coincide with any of these jobs. Indeed, if the device develops a fault between scheduled maintenance the battery might be replaced as part of a repair job. How is the engineer to know (without searching through the service history) whether or not the job that he is currently doing should include the battery change or not?

E-Quip now includes a simple to use maintenance event mechanism. It works like this:

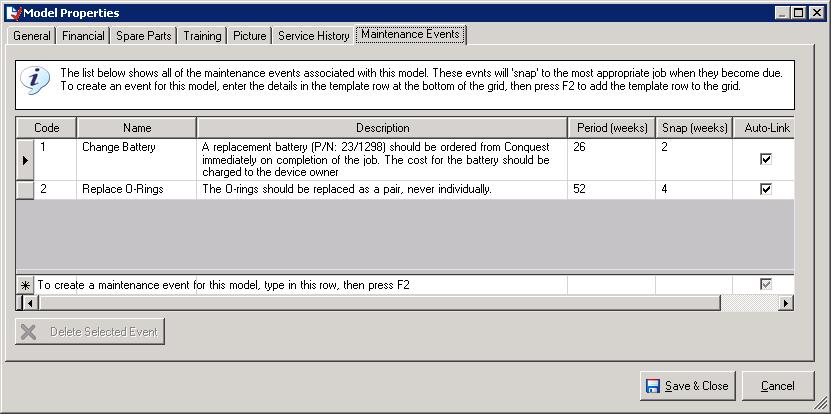

1. On the model screen define which events the device needs, and their interval.

2. If you choose to make these events automatic, that’s all you need to do! Every time you open a device, if any events are due (or overdue) then you will see a list of the events. If you want to you can complete the events directly from the equipment property page.

3. Similarly, whenever you create or open a job for a device which has one or more events due, then you will see a list of the events, and those events will snap to that job. If you complete the event it will be added to the device’s event history, but you won’t hear from it again until it is next due. If you complete the job but don’t complete the event(s), then they will just snap to the next job.

For example:

Step 1: Define an event for a model.

Note that in this example both events are defined with the Auto-Link option.

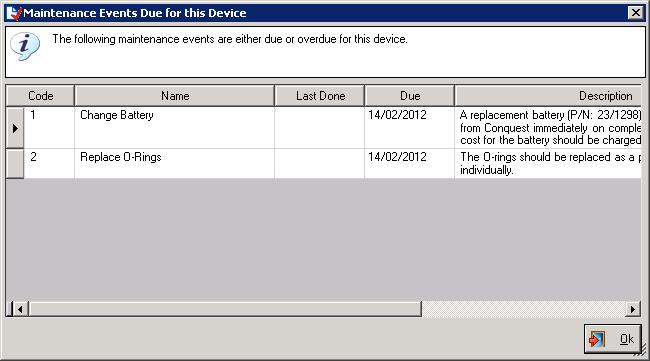

Step 2: Create a job for a device of that type:

As soon as you select the Equipment No. for the job you will be warned about due/overdue events.

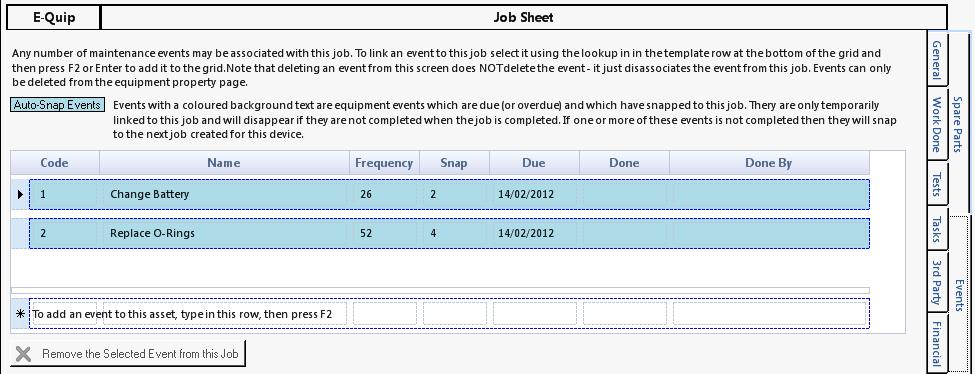

Them when the job opens, the events will automatically snap to the job.

It is possible to manually specify events on the job property page, such as when you wish to carry out an event before it is actually due. Events which have snapped to a job automatically will be coloured light blue. They are only temporarily attached to the job. If they are completed (by entering the completion date) then they will be permanently linked to job and will appear in the device event history.

If an auto-snapped event is not completed and the job is closed, the event(s) will simply snap to the next appropriate job.

This is the simplest scenario but events can be used much more flexibly than this. The next article on this topic will explore this in more detail.